Expert Tips for Selecting the Ideal Rigid-Flex PCB Manufacturer

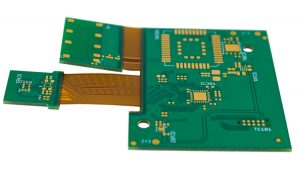

Ideal Rigid-Flex PCB Manufacturer

Choosing the ideal rigid-flex PCB manufacturer requires due diligence to ensure that they can deliver high-quality products on time and within budget. The following tips can help you evaluate and select a manufacturer that can meet your needs and expectations.

First and foremost, look for manufacturers that specialize in rigid flex PCB fabrication. They will have the knowledge and expertise necessary to produce a quality product that meets all your requirements and specifications. This can save you both time and money. Additionally, make sure to request references from previous clients. Ask about their experience working with the manufacturer and inquire about the manufacturer’s adherence to delivery schedules and overall customer satisfaction.

Another important consideration when selecting a rigid-flex manufacturer is to find one that offers quick turnarounds. This will enable you to reduce your production costs and have the flexibility to adjust to changing market conditions. It is also essential to verify that the manufacturer has a robust Quality Management System in place. This will ensure that your rigid flex pcb manufacturer according to the highest standards and are free of defects.

Expert Tips for Selecting the Ideal Rigid-Flex PCB Manufacturer

When designing a rigid-flex circuit board, it is important to take into account the materials used and the thermal expansion coefficients of both the rigid and flexible sections. Failure to do so can result in stress cracking, signal integrity issues, and electromagnetic interference (EMI). Additionally, it is crucial to design for the transition between the rigid and flexible portions of the circuit board. Connector placement is particularly critical as it can impact performance and reliability.

Rigid-flex circuit boards can be extremely durable and are a great option for applications that will be subjected to mechanical stress such as automotive or aerospace environments. They have fewer points of failure, allowing for a more reliable assembly process. Additionally, they have a smaller footprint and are less expensive than traditional printed circuit boards.

Another important factor when evaluating and selecting a rigid-flex manufacturer is to determine whether or not they offer value engineering. This service will allow you to create a prototype of your circuit board and test it before final production. Then, they will make changes to the final product to improve its functionality and performance. This can help you save time and money and avoid costly mistakes during the manufacturing process. This type of service can be offered by many PCB manufacturers.

PCBMay, for example, offers this service and can provide you with exceptional rigid-flex PCBs based on your Gerber file. In addition, this company adheres to ISO and RoHS standards and integrates inspection and testing protocols at every stage of rigid-flex fabrication. In addition, they can produce prototypes in a short amount of time. This makes them an excellent choice for customers with tight deadlines and stringent quality requirements.